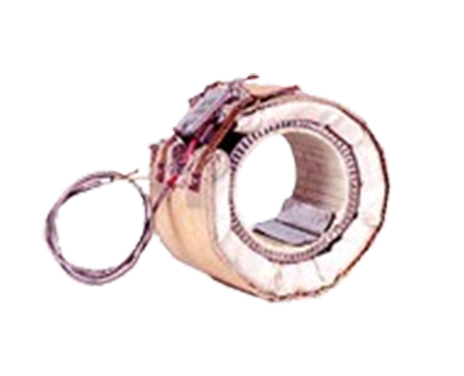

Elmec Insulation jackets are made up of 3 layers. Inner layer is made of fibre glass cloth, Middle layer is made of 50 mm thick fibre blanket, Top layer is made of abrasion proof glass fabric which resists both dirt and plastic material. All these material can withstand temp upto 600° C. These insulation jackets are made with holes and cutouts wherever it is required and so it is easy to install over the barrels of Injection, Extrusion and Blow molding machines.

Insulation jackets are removable, multi-layered covers designed to wrap around equipment such as barrels of injection, extrusion, and blow molding machines.

Its main purpose is to reduce heat loss, improve energy efficiency, and create a safer working environment by maintaining surface temperatures and minimizing heat exposure

Insulation jackets reduce heat loss, energy consumption, and workplace hazards. They also help maintain stable operating temperatures and extend the life of heating elements and equipment.

Insulation jackets decrease the initial heat-up time and help maintain a more comfortable working atmosphere by minimizing radiant heat in production areas. They also reduce the risk of accidental burns by keeping external surfaces cooler.

By trapping heat around the heated component, insulation jackets reduce the load on heating systems. This results in lower power consumption, shorter heating cycles, and reduced CO₂ emissions in line with sustainability goals.

Insulation jackets are ideal for use on barrels of injection molding, extrusion, and blow molding machines, as well as other process equipment where heat retention and energy savings are priorities