Elmec is a leader in the heater industry by manufacturing high quality ceramic band heaters. Our Ceramic Insulated Band Heaters can meet the demand for energy conservation & operation efficiency.

Elmec ceramic band heaters are custom made and are used in various applications including heating plastic machine barrels, Dies, nozzles, drum heating, Pipe heating, Incinerators, lead mealtin, etc.,

We use high quality Steatite insulators, Nichrome resistance wires for serving high temperature applications. Recent development in polymers requires high processing temperature for specific applications and our heaters serves this purpose perfectly.

Elmec Ceramic band heaters are used by leading OEMs and Plastic processing industries. We are supplying to Indian and overseas industries / markets.

Elmec is first to develop ceramic band heaters for napkin incinerators and proven in its application by supplying to countries leading napkin incinerator manufacturers. Our heaters are good for temperature as high as 850 deg cen. and exclusively made for this purpose.

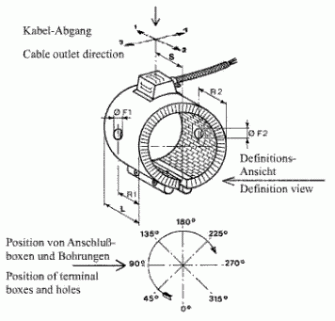

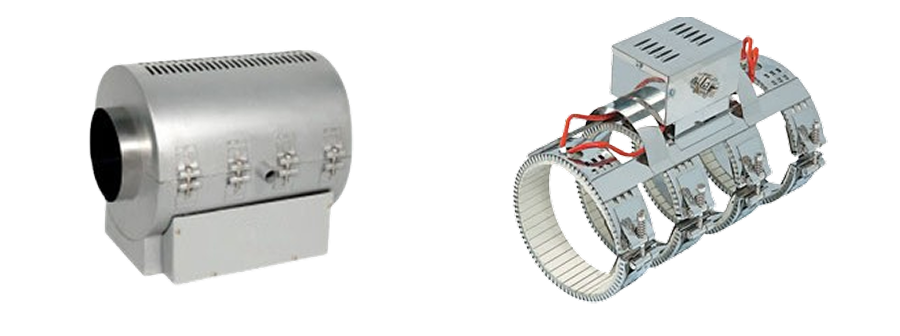

Elmec also manufacture ceramic band heaters with cooling cover and heaters with copper, Aluminum fins. Consult with us before sending enquiry for such heaters requirements. We can supply heaters for your existing blower cover / blower. Customer need to give correct dimensions to execute such supplies.

Ceramic Band Heaters are highly efficient industrial heating elements designed to provide uniform and consistent heat to cylindrical surfaces. They utilize high-grade ceramic insulation to allow for higher operating temperatures and excellent thermal transfer, making them ideal for a wide range of industrial applications.

Key advantages include superior energy efficiency due to ceramic insulation, excellent heat transfer and uniformity, robust construction for extended operational life, and the ability to achieve higher operating temperatures compared to other band heater types. Their design minimizes heat loss, contributing to lower energy consumption.

Ceramic Band Heaters are widely utilized in industries requiring precise and efficient heating of cylindrical parts. Common applications include plastic processing machinery (e.g., injection molding, extrusion barrels), pipe heating, tanks, drums, and other cylindrical process equipment in various manufacturing sectors.

Their energy efficiency stems from the use of ceramic insulation and an internal ceramic fiber mat. This design significantly reduces heat loss to the ambient environment, directing more heat towards the heated surface. This allows for lower sheath temperatures and more effective heat transfer, resulting in reduced power consumption.

Uniform heat distribution is achieved through the precise winding of the resistance wire within the ceramic segments, which are designed to provide consistent spacing and contact with the heated surface. The ceramic insulation and internal fiber mat also contribute to directing heat efficiently and evenly across the band.