Elmec Ceramic Cartridge Heaters are custom made and are used in various applications including heating of Ovens, Dryers, Water and Oil heating. Ceramic cartridge heaters are good at places where indirect heating is required. We have developed heaters to a maximum capacity of 320 KW. Ceramic cartridge heaters assembled in SS 304 tube sheath and assembled to ANSI flanges of various sizes for oil heating applications.

We use high quality ceramic insulators, Nichrome / kanthal D resistance wires.

We can also supply with outer casing and flange of thread type or disc type as per customer specifications. These heaters come with screw terminals.

Elmec Ceramic cartridge heaters are used by leading OEMs and Cement, Pharmaceutical, Food processing, Metal processing industries, plating shops. We are supplying to Indian and overseas industries / markets.

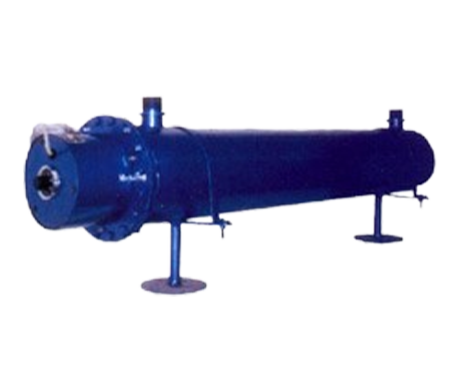

Circulation heaters, also known as an in-line heater, are electric heating devices designed to heat fluids as they flow through a vessel. Its main applications include water heating, freeze protection, heat transfer oil, fuel oil, steam, air, and various gases in industrial processes.

These heaters are suitable for a wide range of fluids, including water, heat transfer oils, fuel oils, steam, air, and gases. The design ensures efficient heating and reduced viscosity, making fluid transfer easier and more energy efficient.

Circulation heaters provide high thermal efficiency, quick heat-up times, compact design, and precise temperature control. They help reduce energy loss and improve heating uniformity in closed-loop systems.

Circulation heaters are ideal when you need rapid, uniform heating of fluids in a closed-loop system, especially for high-pressure or high-temperature applications where direct immersion or external heat sources are less effective.

By applying direct electric heat to the fluid as it passes through the vessel, the circulation heater lowers the fluid’s viscosity. This makes it easier to pump or transfer fluid through pipelines or processing equipment.

While both use tubular heating elements, immersion heaters heat stationary fluids in a tank, whereas circulation heaters heat moving fluids in a closed pipeline, offering continuous process heating and better thermal transfer.