Elmec manufactures and supplies industrial and laboratory furnaces for Die heating, Annealin, Tempering, Hardening, and Softening of metals.

Elmec Specialized in energy efficient Infrared Furnaces for temperatures up to 800 deg cen… These are used where quick heating of metals is required.

We have supplied similar furnaces for nonferrous metal forging industries for forging small components in copper and aluminum and succeeded in customer satisfaction.

For more information on technical specifications consult ELMEC.

Industrial furnaces are high-temperature heating systems used to heat metals, ceramics, glass, and other materials during production. It works by generating and maintaining controlled heat through electric or fuel-based sources.

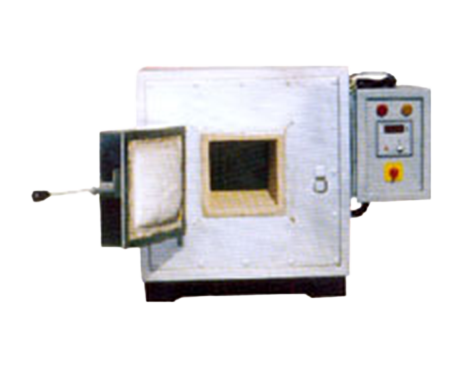

We use high-grade insulation, nichrome or Kanthal heating elements, PID control systems, and robust steel outer casings to ensure safety, energy efficiency, and long-lasting performance

We provide options in temperature range (up to 1200°C+), chamber size, sensor type, controller interface (digital, touchscreen), and programmable cycles, tailored to industry-specific needs.

Temperature is regulated using advanced controllers and sensors, such as thermocouples or RTDs, which provide real-time feedback to maintain setpoints and ensure process consistency and safety

Important features include operating temperature range, thermal efficiency, burner or heating element technology, refractory lining quality, automation and control systems, and built-in safety mechanisms like emergency shutdown and flame monitoring