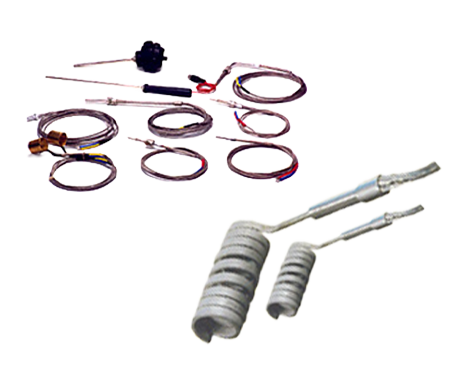

Hot runner heaters come in various types, including coil heaters, nozzle heaters, and manifold heaters. Coil heaters are compact and versatile, with a coiled heating element that provides uniform heat distribution. They are commonly used in nozzle tips and sprue bushings. Nozzle heaters are designed to fit into the nozzle of the injection molding machine and provide direct heating to the molten plastic. Manifold heaters are used to heat the manifold of the hot runner system, ensuring proper temperature control for multiple cavities.

Hot runner heaters are critical components in the plastic injection molding process. Their primary function is to maintain the optimal temperature of the molten plastic as it flows through the hot runner system, which is crucial for ensuring precise and consistent results in the final molded parts.

Hot runner heaters are widely used across various industries, including automotive, packaging, consumer goods, medical, and electronics. They are ideal for producing high-quality, complex plastic parts with tight tolerances.

Common applications for hot runner heaters include the production of automotive bumpers, medical device components, bottle caps, and electronic enclosures, among others. They are chosen for these applications due to their ability to minimize material waste and reduce cycle times.

Hot runner heaters offer several significant advantages:

Hot runner heaters eliminate the creation of "runners," which are the waste material generated in traditional injection molding. This directly translates to significant material cost savings and reduces the overall environmental impact by minimizing plastic waste.

Hot runner heaters come in various types, each designed for specific applications within the system: