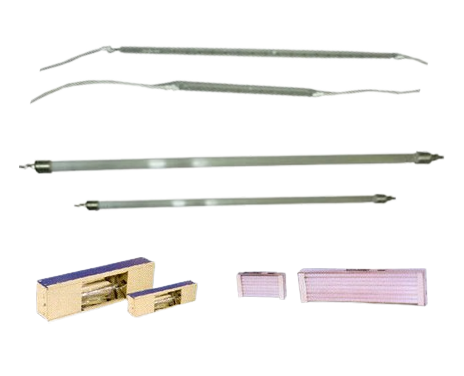

Elmec supplies imported short wave (SW) infrared Heaters. These are available in standard sizes. Wattage from 500 to 4000 and Volts 230 / 415.Medium wave (MW) infrared heaters are made using Silica / Quartz tube and nickel chromium resistance wire. These are made as per customer’s specifications

Short wave infrared heaters emit high-intensity radiation and penetrate deeper into materials, making them ideal for fast heating. Medium wave heaters emit gentler, broader heat, best suited for surface heating and drying applications.

Both types are used in industrial and commercial settings for PET preform heating, paint baking, rubber coating drying, printing ink drying, powder coating curing, impregnation plants, paper coating drying, laminations, and screen printing on textiles and T-shirts

They use halogen-filled quartz tubes with tungsten filaments that heat up instantly and emit radiation in the 0.75–1.4-micron range, providing fast, focused heating with minimal energy loss.

Medium wave heaters emit wavelengths between 1.5–5 microns and operate at lower temperatures than short wave models. They provide even heat distribution and are less likely to overheat sensitive materials.

Short wave infrared heaters heat up almost instantly, reaching full output within a second, while medium wave heaters typically reach operating temperature in under 30 seconds.

Short wave infrared heaters are ideal for spot heating, outdoor areas, and industrial processes that demand rapid, high-temperature output. They are especially effective where immediate heat and high efficiency are required.