Elmec thermocouples are specially made under stringent quality conditions

A thermocouple is a simple yet efficient sensor that helps to measure temperature. Two notable wire legs, which has been made up of different metals are welded at one end to create a junction where we measure the temperature. The changes in temperature will create a voltage. Then the temperature can be easily calculated with the help of thermocouple’s reference table. Thermocouples are preferred to be used in temperature scales from -200 to 2316 °C or -328 to 4200 °F.

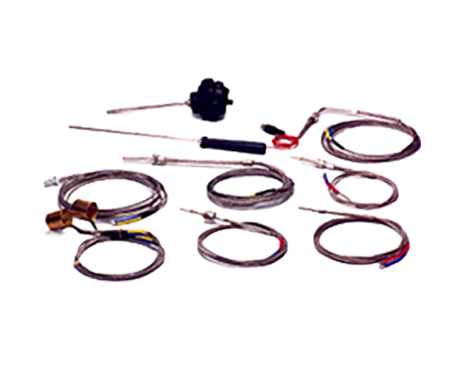

We have many types of thermocouples. Every thermocouple has its uniqueness in terms of durability, vibration resistance, chemical resistance, temperature range, and application compatibility. J, K, T, & E will be denoted as the “Base Metal” of thermocouples, and it is the most commonly used thermocouples. The “Noble Metal” thermocouple includes Type R, S, and B, which are used in high-temperature applications. Elmec Heaters presents a wide variety of thermocouples and thermocouple replacements for largest market applications. Elmec Heater’s thermocouple sensors are managed, examined and scrutinized before it gets shipped.

Thermocouples are temperature sensors made by joining two different metal wires at one end to form a junction. When this junction experiences a temperature change, it generates a voltage that can be measured and converted into a temperature reading using reference tables.

There are different types of thermocouples such as Type K, Type J, Type T, Type E, Type N, and more, each with specific temperature ranges and characteristics.

Thermocouples offer fast response, high temperature range, rugged construction, and cost-efficiency. They’re ideal for harsh industrial environments like extrusion, ovens, and metal processing.

Grounded thermocouples offer faster response times and are ideal for applications with rapid temperature changes. Ungrounded types are better for electrically noisy environments, as they provide isolation from the circuit.

Install thermocouples in direct contact with the process medium. Avoid installing near electromagnetic sources and ensure proper grounding to minimize noise and signal interference.

We use high-purity alloys, ceramic or stainless-steel sheaths, mineral insulation, and precision welding techniques to ensure stability, fast signal transmission, and high resistance to corrosion and thermal shock.